Safely and easily remove the spray chrome metal without harming the base coat.

Cosmichrome keeps minor mistakes from becoming disasters.

Cosmichrome is the only spray chrome that allows you to safely and easily remove the spray chrome metal without harming the base coat. If you notice a defect in your plating you can just remove the silver with bleach, then re-spray the Cosmichrome! No need to sand and re-apply the base coat!

Touching the base coat of competing spray chrome products is forbidden. Touching the base coat ruins their base coat finish and it will have to be sanded and re-applied. This drawback can add days to your project, sanding and waiting for base coat to dry. Cosmichrome allows you to simply remove the metal layer and re-spray the metal. This is a major technical advancement in spray chrome. Everyone makes a mistake once in a while.

Achieving a perfect chrome spray plating is easy when you remain aware of all the parameters that can have an impact on the results. Like all professional paint projects, these parameters range from temperature, humidity, dust, fingerprints, and so on. Thankfully, there is a way to salvage your part without having to sand your part and re-apply the base coat! Bleaching the base coat to re-plate a part is easy to do with Cosmichrome BCL base coat.

Bleaching A Part For Re-Plating

BLEACH THE PART!

WHAT YOU’LL NEED:

- RUBBER GLOVES

- MICROFIBER CLOTH

- SOFT BLUE SHOP TOWELS

- CUP OF BLEACH

- COSMICHROME BASECOAT CLEANER

- THE PART TO BE BLEACHED

*NOTE: This process can only be done if the Topcoat has not yet been applied to the part.*

THE PROCESS

The part that needs re-plating will need the plating to first be removed.

We begin this process by saturating our soft blue shop towels into the cup of bleach. After it is well saturated, gently rub the bleach into the part. The chrome should begin to quickly dissolve and reveal the Basecoat underneath. Continue to rub and wipe away the plating until all the plating is removed. Re-soak your shop towel in bleach and remove any residual plating residue. Grab a new shop towel, soak in bleach and wipe down the piece as a final rundown. Now rinse your part very thoroughly with distilled water to remove any leftover bleach. Be aware that any leftover bleach will oxidize the metal and make the product look yellow! So rinse very well!

Now that the old plating is gone, we can prepare the part for re-plating.

Apply Cosmichrome Base Coat Cleaner to the part to clean the base coat for re-plating. Gently rub in the Basecoat Cleaner into the part. Be careful to not apply too much pressure. Now, rinse away Basecoat Cleaner with distilled water.

Now re-flame the part to prepare it for re-plating. After that, apply the A22 Activator solution. This activates the Basecoat for plating adhesion. Rinse again with distilled water, getting rid of any excess A22.

Time for re-plating.

Apply G4 & G5 plating solutions. Rinse with distilled water.

Congratulations! You have successfully re-plated a part!

Follow us on Facebook. https://facebook.com/cosmichrome

Follow us on Instagram https://Instagram.com/cosmichrome

Spray Chrome Problems: Performing a Glass Test

Spray chrome problems: Performing a glass test

A glass test is an easy way to test your chemicals and machine for proper operation to avoid spray chrome problems. No base coat is needed. Just wash a piece of glass with our base coat cleaner and distilled water. Rinse it well then activate and plate it. No flame treatment is needed on glass.

If the Cosmichrome finish looks good on glass, then it will look just as good on base coat.

Contact us for help if your glass test result is poor. We will help you find the issue causing the problem. The Master System Pro has a built in cleaning system that keeps your machine in proper operating condition to avoid these problems.

The Mini System Pro: Economical Spray Chrome System

Click the image to view an introductory video on the Mini System Pro

Check out our new Cosmichrome Mini System PRO™. A precise, dependable and inexpensive spray chrome machine for plating parts on a smaller scale. Great for 3D prints and helmets.

The Mini System Pro uses separate guns for each step. The Mini System Pro dual gun will provide a precise 50/50 balance of the G4 and G5 products for brilliant chrome plating. It is limited to small parts. If you need to plate larger parts bigger than a hubcap you will need our Master System Pro™

Base Coat Cleaner

Our new Cosmichrome Base Coat Cleaner will be available in June. It’s the first and only spray chrome base coat cleaner on the market. It safely and thoroughly removes contaminants such as fingerprints and overspray from the base coat without having to reapply the base coat. It does not leave a residue and the silver can be plated without worries of contaminants. Most spray chrome base coats can’t be touched at all let alone cleaned if needed. Cosmichrome is tough! If you accidentally touch the base coat on one of your parts you can simply clean off the contaminants and proceed with the plating process!

Works much better than distilled water alone.

Cosmichrome base coat is the only spray chrome base coat that is tough enough to be cleaned if it is touched or contaminated. All competing base coat finishes are ruined if the base coat is touched. With Cosmichrome you don’t have to sand and start over. Just use our cleaner and then finish the process.

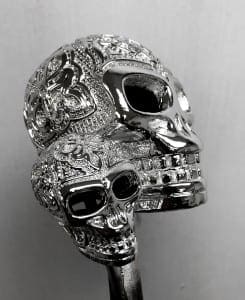

How to apply a chrome finish to a 3D print

If you are looking for how to apply a chrome finish to a 3D print your answer is here. Cosmichrome is ideal for applying simulated gold, chrome, copper and nickel finishes to 3D prints. The finish is applied in a paint booth. Most 3D model shops already have paint facilities so Cosmichrome is a logical addition to 3D part production. In this example the skulls are SLAs. I believe they were made in an Objet brand printer but I am not certain. They had a waxy residue from the setup material that I cleaned off with a toothbrush and alcohol. I mounted the prints to dowels using hot glue. Then I applied an Epoxy primer because I wasn’t certain how well I had removed the residue. Unfortunately the primer never hardened so I removed it with lacquer thinner and got fresh epoxy primer from the local paint store. I then let the primed part and let it dry over night at room temperature.

Then I applied Cosmichrome base coat. I applied three layers to be sure I got good coverage down in the low spots in all the detail on the model. I let the base coat dry over night at room temperature. The base coat can also be baked to speed up the drying process but on delicate 3D prints heat can distort the shape of the part so room temperature drying is the safest choice. After the base coat was completely dried I flame (plasma) treated the base coat then proceeded to the plating process you can watch in the video below.

I let the part air dry in front of a fan for about twenty minutes and then applied the top coat. Here is the final result.

You can clean our base coat!

The latest update to the Cosmichrome base coat features a fantastic new feature. If someone accidentally touches the base coat you clean our spray chrome base coat with distilled water and a damp paper towel. Until now the part would dave to be sanded and sprayed with base coat again. It’s simple and easy.

If someone accidentally touches the base coat after it is dry you can clean off the fingerprints without any harm or damage to the final finish. All you have to do is wipe the fingerprints off with a soft paper towel that has been wet with distilled water. Then re-flame the base coat and proceed with plating as usual. This base coat is also extremely easy to apply and is very resistant to runs and drips. As usual the adhesion of the metal and top coat are exceptional.

This new feature solves one of the more demanding requirements of applying spray chrome coatings. Typically their base coats are very sensitive to accidental touches and other types of minor contamination. This would often lead to frustration when an curious coworker would decide to handle and inspect the parts being coated. Now one can just clean the fingerprints off rather than having to sand and reapply the base coat.

Additionally Cosmichrome base coat is still the only base coat that can’t be over dried. The dryer it is the better the adhesion of the metal and top coat. Other products are much more sensitive to over drying and loss of adhesion.

You can let our base coat dry all weekend or even all week and there will be no loss of metallic adhesion.

As always, Cosmichrome is the only spray chrome product guaranteed not to turn yellow. That is just one of the many reasons it is the spray chrome of General Motors, Andretti Autosport and West Coast Customs to name a few.

Rose Gold is Hot!

Rose gold is very fashionable at the moment. We manufacture rose gold for electroplating that is very popular with jewelers and some people are plating car emblems with our brush rose gold too. You can simulate rose gold using Cosmichrome to take advantage of the rose gold surge in popularity. This is a sample of rose gold colored Cosmichrome created in our Montreal office.

Call or email us for the easy to mix formula.

Base Coat and Top Coat Updated for 2014

These chrome valve covers were spray chromed by our customer Sacramento Chrome and Paint https://sacchromepaint.net using our latest Cosmichrome base coat and top coat. They appear to be disappearing into the table or made of glass because the finish is so perfectly smooth and the color so accurate.

We have been able to significantly accelerate the drying of the top coat so your parts are ready to ship sooner.

The new base coat and top coat are in stock and ready to ship.

Spraying Chrome Instructions

Spraying Chrome Instructions. How to Apply Cosmichrome Base Coat

V-BCL Base Coat 100 grams

V-BCL-CAT catalyst 40 grams

Reducer- None needed

Mix for 2 minutes before spraying.

Use a scale to measure the paints. Do not use ratios on mixing cups.

PLEASE NOTE THAT ALL PARTS MUST BE PREPAIRED PRIOR TO APPLIYING THE COSMICHROME BASE COAT. PARTS MUST BE SEALED AND WET SANDED WITH MIN 800 GRIT SAND PAPER. BCL BASECOAT WILL NOT COVER OR HIDE ROUGH IMPERFECTIONS ON THE SUBSTRATE.

Recommended primers: either urethane, epoxy or polyester. Primer must be catalyzed and must be completly dry before applying base coat. Spray chrome application requires completely dry base coat and primers.

Spray application

Adjust the spray gun as follows

35-40 PSI at the gun, (2 bars) lower pressures will cause the paint to dry slower so be careful

Wide open fan

Needle open 1 1/2 to 2 turns

Spray the substrate with one medium wet film in a cris cross pattern and let stand for 10 min.

Spray a wet second coat after 10 min have elapsed.

Once you are satisfied with you application allow 30 min to dry naturally before baking or allow to air dry at normal room temperatures and above.

BAKING BASE COAT

It is critical that the base coat is completely and properly dried! When in doubt such as on large or heavy parts or parts with heavy coats of base coat, dry the base coat longer. It is not possible to over dry the Cosmichrome base coat.

If you have applied a primer or other paint on a part first that paint must be completely cured before applying our base coat. If the base coat is wet or a primer beneath the base coat is wet then the final finish can discolor or appear foggy and intra-coating adhesion will be weak. Allow primed parts to bake for 1 hour to 1 hour 20 minutes at 140 F / 60 C

Longer dry times are fine if your part is large or has a lot of paint. The base coat can’t be over dried!

Higher temperatures can reduce baking time.

Allow parts to cool down to room temp before continuing the process.

NATURAL AIR DRY FOR BASE COAT

Once you have finished applying 2 or 3 coats, let the parts dry in a dust free environment (closed room) for 15– 24 hours minimum at room temp. Small parts dry faster. Large parts take longer to dry properly. When in doubt allow the base coat to dry longer. Our Base coat can’t be over dried so there is nothing to worry about drying parts longer. Even if you bake the part and want to wait until the next day or over the weekend to plate there will still be excellent adhesion. We have accidentally baked parts at 320ºF for 1 hour and the adhesion was still excellent. The base coat discolored and turned brown and it did not damage the coating.

Please note if you have sprayed more then 2 coats of base coat allow more dry time, 24 hours minimum. Minimum!